An Introduction to Laser Cutters

Laser cutters also produce number dirt if they reduce and create a cut point that’s nearly negligible. Also newer lasers cutters require less power to work than lasers of days gone by and are also smaller sized and mobile.

They’re just some of reasons why laser blades are obtaining their way into smaller stores and businesses that in the past might have found them much too expensive to afford. Why could a shop owner acquire a best laser engraver for small business when you can find presently mainstream cutters in the tool cabinet? A very important factor that laser cutters may accomplish that conventional blades can’t is do clean reductions through on strange shaped objects. Also being that laser blades generate number dust, complicated conversions and changes are incredibly faster and simpler to do.

Which means that complex bits of delicate machinery may be cut without having to be disassembled. Also clear straight lines may be cut immediately through, no matter what shape a thing is or what it is created of. Lasers will also be great for opening punching and engraving and yet again, they leave no dust or metal particles in the process. Also new laser engravers may engrave words and photographs on nearly any type of material. This is the reason small shop and business owners are now doing custom technical and creative work that they never would have imagined probable in the past.

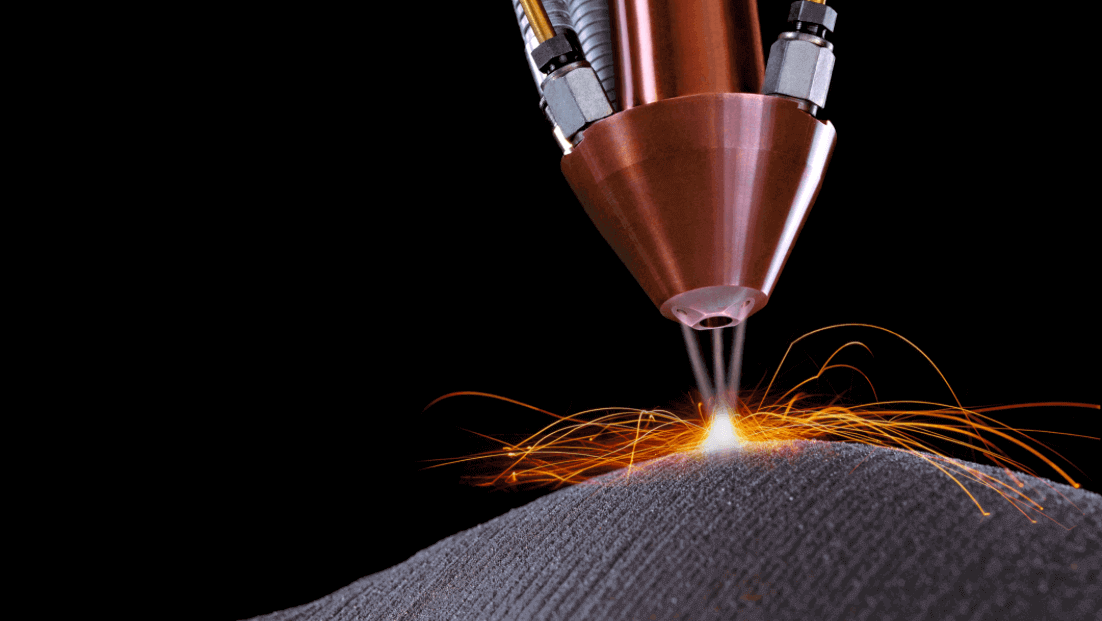

Utilization of laser cutters is quite frequent today. The past few years have experienced many huge manufacturing plants in addition to small companies changing their traditional mechanical chopping devices with sophisticated laser cutters. The primary reason behind the large popularity enjoyed by these chopping models is their ability of offering precision. These machines use high power laser supports for chopping steel elements easily and with good perfection. This informative article can tell you about the functions and features of laser cutters.

As mentioned over, these models were created mainly for cutting material parts. To be much more accurate, they are most useful suited to chopping metal and carbon steel. They are usually not employed for cutting through copper and aluminum alloys as those metals absence the power of highlighting light. Authorities also don’t recommend applying laser cutters for chopping those alloys as alloys that have copper or aluminum as you of these components also lack the capability of absorbing and completing heat. For cutting through copper and metal alloys, you should use stronger laser beams.

You can find certain details that you need to be aware of before using laser cutters. One of the most crucial ones among them is that when these models are useful for making openings in a metal human body, the leave diameter is usually smaller than the access diameter. This may noise strange for some, but professionals say that this really is one of many biggest benefits of applying these cutting devices.

Laser cutting is really a process which first came into used in the late1960s for professional applications. It works by aiming a high-powered laser, frequently a CO2 laser, about the design that needs to be cut often utilizing an car CAD file. Because this is a very precise, precise approach to cutting, and since it generally does not require an actual chopping blade which can become broken and broken, it is fantastic for manufacturing components. Since the engineering evolved and became more generally accessible, manufacturers began to see the potential of laser chopping to transform their a few ideas into reality. Laser engraving is using the same strategy to render a design at first glance of a material.